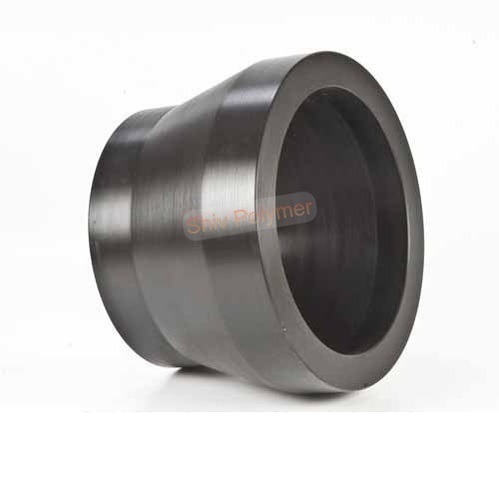

HDPE Reducer

Price 20.00 INR/ Piece

HDPE Reducer Specification

- Product Type

- HDPE Reducer

- Material

- HDPE

- Connection

- Butt Weld / Socket Fusion

- Thickness

- 10 mm

- Standard

- IS 4984 / ISO 4427 / DIN 8074

- Technics

- Injection Molded

- Surface Treatment

- Smooth Finish

- Length

- 120 mm to 400 mm (varies as per size)

- Wall Thickness

- 10 Millimeter (mm)

- Nominal Pressure

- PN 6/PN 10/PN 16

- Color

- Black

- Temperature Range

- -40C to +60C

- Feature

- Corrosion Resistant, High Impact Strength

- Sizes Available

- 20 mm to 630 mm OD

- Application

- Water Supply, Chemical Transportation, Irrigation, Plumbing

- Hydrostatic Test Pressure

- As per application and standard

- Density

- 0.9410.965 g/cm

- Compatibility

- Suitable with HDPE pipes of corresponding diameter

- End Type

- Plain End

- Shape

- Reducer (Concentric/Eccentric as per requirement)

HDPE Reducer Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 4 Days

- Main Domestic Market

- All India

About HDPE Reducer

HDPE Reducer

Product details

| Wall Thickness | 10 KG |

| Country of Origin | Made in India |

| Material | HDPE |

| Connection | Welded |

| Usage/ Application | Plumbing |

| Material Grade | PE100 |

| Fitting Type | REDUCER |

| Brand | shiv |

| Size/ Diameter | 20 mm to 350 mm |

Superior Durability and Strength

HDPE Reducers are engineered to withstand demanding environments, with high impact strength and excellent corrosion resistance. These reducers ensure reliability in critical installations such as water supply and chemical transport systems, making them a long-term solution for infrastructure projects.

Versatile Sizes and Standards

Available in diameters ranging from 20 mm to 630 mm OD and wall thickness of 10 mm, our HDPE reducers cater to a broad spectrum of applications. Each reducer is manufactured in accordance with recognized standardsIS 4984, ISO 4427, and DIN 8074guaranteeing compatibility and performance.

Efficient Connection Technology

With plain end designs, these HDPE reducers support secure butt weld and socket fusion connections, facilitating hassle-free installation. Their injection molded, smooth finish eliminates chances of leakage and ensures consistent flow and structural integrity throughout the system.

FAQs of HDPE Reducer:

Q: How is an HDPE Reducer used in piping systems?

A: An HDPE Reducer is installed between two HDPE pipes of different diameters to ensure smooth transition and flow within water supply, chemical transportation, irrigation, or plumbing setups. It is joined using butt weld or socket fusion techniques for a leak-proof connection.Q: What types of HDPE Reducer shapes are available and how do I choose?

A: HDPE Reducers come in concentric and eccentric shapes. Concentric styles align pipes centrally, ideal for vertical drops, while eccentric are designed for horizontal runs, preventing pooling and facilitating better drainage. Selection depends on your pipeline layout and flow requirements.Q: When should I use an HDPE Reducer in my piping system?

A: HDPE Reducers should be used whenever pipes of differing outer diameters need to be joined in projects such as water supply, chemical transport, irrigation lines, or plumbing. They help maintain system pressure and ensure efficient fluid movement},{Q: Where can I source HDPE Reducers in India?

A: HDPE Reducers are readily available from authorized dealers, manufacturers, wholesalers, and suppliers across India. Look for distributors who offer products certified to IS 4984, ISO 4427, or DIN 8074 standards for optimal quality and compliance.Q: What is the process for installing an HDPE Reducer?

A: Installation involves welding the plain-ended HDPE Reducer to corresponding pipes using butt weld or socket fusion methods. The process ensures a robust and seamless joint, suitable for hydrostatic pressure tests as per standards and specific application demands.Q: What are the benefits of using HDPE Reducers?

A: HDPE Reducers offer corrosion resistance, high impact strength, and reliable performance across a broad temperature range. By meeting international standards and providing smooth, leak-free connections, they contribute to low maintenance costs and long service life in piping systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipe Fittings Category

HDPE Spigot Tee

Price 100 INR / Piece

Minimum Order Quantity : 1000 Pieces

Length : Standard or as specified (customizable)

Color : Black

Standard : Other, IS 4984, ISO 4427, DIN 8074

Technics : Other, Injection Molded / Fabricated

HDPE long Neck Pipe Collar

Price 25 INR / Piece

Minimum Order Quantity : 1000 Pieces

Length : Customizable

Color : Black

Standard : Other, IS 4984 / ISO 4427

Technics : Other, Injection Moulding

HDPE Long neck with flange

Price 100 INR / Piece

Minimum Order Quantity : 200 Pieces

Length : Standard or as Per Requirement

Color : Black

Standard : Other, IS 4984, DIN 8074/8075 or Equivalent

Technics : Other, Injection Moulded or Butt Welded

HDPE Pipe Fittings

Price 7 INR / Piece

Minimum Order Quantity : 500 Pieces

Length : As per fitting type (Generally compact pieces)

Color : Black

Standard : Other, IS 4984 / ISO 4427 / DIN 8074 / ASTM F714

Technics : Other, Injection Moulded / Fabricated

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry